Drones, Bearings, & Self Impregnation

Here’s something quick and interesting I found while performing a teardown.

I really enjoy flying drones. As an FAA Licensed Commercial Drone Pilot and co-founder of an aerial production company, I’ve managed to keep my hobby alive and justify the inordinate amount of time I’ve spent doing it. However, high use means high wear on my equipment. Specifically, I’ve had an issue with the landing gear on my DJI Inspire1.

After checking the forums, It appeared my issue was that the worm drive was all gunked up. The landing gear essentially is retracted by winding a giant screw with a servo, and having a bearing slide up and down that screw. The gear pivots in an X fashion making a short travel distance raise the gear a substantial amount.

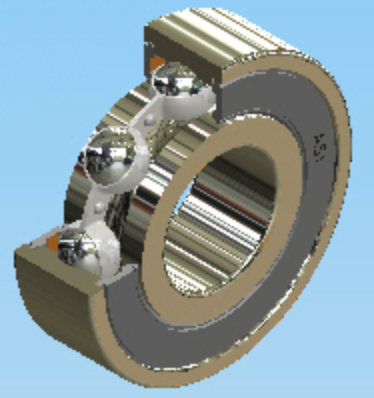

But enough about the gear, Basically I found the bearing that seemed to have all the gunk in it. Unfortunately, after removing the cap holding it in place, the bearing seemed to fly apart. Little balls went everywhere (fortunately I was in a sandboxed area) and I was presented with the shaft, collar, and bearing cage. However, the bearing cage seemed to be made of some sort of resin material. I had never seen a bearing like this before (and, due to its falling apart, decided to order a replacement from our good friends at McMaster Carr) so decided to do some digging to see what I could uncover about it. Was this a custom Chinese bearing? Was it a cheap imitation like a lot of things that come from china?

As it turns out, the cage is made of Phenolic Resin. But thats not the part that amazed me. These bearings (with a very large operating temperature range) are actually self lubricated, by being vacuum impregnated with oil.

Essentially, vacuum impregnation is when the materials (cage) are subject to very high heat (about 1200 degrees Fahrenheit) and a very strong vacuum. Then, lubrication oils are introduced into the chamber, coating the material. Next, the vacuum is released, and the oil is forced into the material. The result is a material that is literally seeping lubricant, and will keep expelling it for time to come as the bearing is used. While I’m not quite sure what caused the bearing to fall apart, I assumed it would be a pretty safe (and cheap) decision to replace the entire bearing, especially if the lubricating bearing had run out.

Also, a quick piece of advice? Use dry lubricant. It doesn’t attract as much dust as the grease.

So there you have it. An accidental teardown of my drone caused me to learn something I definitely didn’t know before. Hopefully you learned something too.

Here’s a great article on bearings incase the topic interests you more: https://www.astbearings.com/ball-bearing-cages-retainers-ball-separators.html